Heavy equipment may look sturdy and impregnable, but each unit is composed of a myriad of sensitive parts that need no small amount of care. Storing heavy machinery requires some preparation to prevent it from getting damaged.

Different climate conditions can harm equipment. Cold weather can cause:

- Vital car fluids (e.g. radiator, transmission, brakes, engine, and hydraulics) to thicken, preventing them parts from functioning properly

- Battery discharge, which increases the difficulty of starting up equipment

- Tire pressure to decrease (one PSI for every -17 degrees Celsius)

Hot and dry weather can cause:

- Excess stress on mechanical parts, wearing them down much faster and leading to premature breakage

- Rubber parts (e.g. tires, hoses, gaskets) to break apart or disintegrate

- Water in batteries to evaporate, compromising the lead plates in the cells and causing a short so that the machine is unable to start

Preparing Heavy Equipment for Storage

When the situation calls for you to keep machines idle, whether it’s the turn of the season or the end of a project, properly store your equipment to prevent damage, costly repairs, and project delays. This way, when your machines are needed again, they are in full working order and can be used at a moment’s notice.

Below are a few tips you can follow to preserve the condition of your equipment and extend its lifespan:

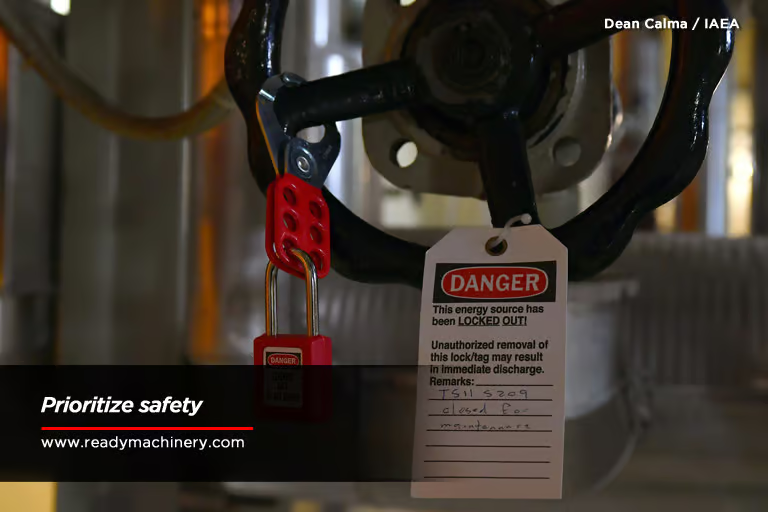

- Implement lock-out/tag-out protocols – Even equipment that is turned off can be dangerous. Lock-out/tag-out practices are an essential step in workplace safety, enabling companies to protect workers from accidents.

- Clean it – Dirt and debris can damage parts when left unattended for long periods. They can cause blockages or degrade components. Cleaning your equipment can prevent damage.

- Lubricate moving parts – You should also consult your owner’s manual and properly lubricate any moving parts at points of contact before storing your equipment.

- Inspect the tires (if applicable) – Make sure pressure is slightly over-inflated to keep the tires from flattening when left unused. One alternative is to use jacks to lift the tires, and another is to store machinery off the ground by placing it on railroad ties or treated lumber.

- Tighten nuts and screws to keep parts in place.

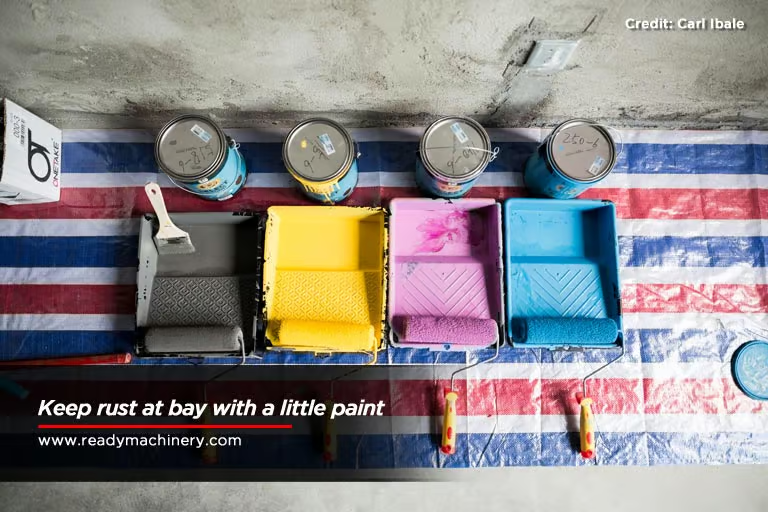

- Paint over chipped areas to protect the body from rust. Examine the body and take not of exposed parts so they can be sealed with a fresh coat of paint.

- Make it accessible. Doing so makes it easy for the engine to be fired up at least once a year for maintenance or checks. Let it face toward the pathway (or wherever the foot traffic is) to keep identification numbers visible for inventory purposes.

- Check fuel levels. When storing equipment during the winter, fill the tank to prevent condensation from contaminating fuel lines when the spring thaws. When storing winter equipment in the spring, drain the fuel with a siphon to prevent gum deposits and rust from forming in the tank.

- Space equipment properly. Making sure there is ample space between machinery will prevent collisions.

- Repair damage. Any amount of damage, no matter how minor, incurred during a job should be taken care of to keep it from degrading and turning into a major issue. This also prevents you from having to make costly repairs when the machine is recommissioned.

- Perform maintenance as instructed by the user guide. Take note of the parts that may need replacing at the end of a season.

- Install security cameras in your storage site, or if you’re renting a facility, make sure they have 24/7 surveillance. There is a wide variety of security cameras in the market with a wide range of features. You can choose one that can feed footage into your mobile or one with alarms

- Keep equipment indoors. Whether you’re storing machinery during the summer or winter, invest in an indoor storage area. Direct exposure to the elements for prolonged lengths of time can cause rust and damage equipment.

Storage Options for Heavy Machinery

Effective storage solutions include:

- Shipping Containers

Shipping containers have served a broad range of purposes from being used as retail facilities to low-cost housing. Watertight and durable, they are an effective and inexpensive means of housing objects from the simplest sporting goods to heavy machinery and equipment.

Construction companies typically use shipping containers to keep tools, supplies, and equipment secure on a project site. Shipping containers are available for either rent or purchase and come in a variety of shapes and sizes to suit various applications. They can also be modified depending on preference and need and can be fitted with:

- Electrical outlets

- HVAC

- Insulation

- Shelving and racks

- Lighting fixtures

- Vents

- Windows

Shipping containers can be secured with a lock to prevent theft or unauthorized use of equipment and tools.

- Storage Units

Storage units are available in a wide range of sizes and can be commissioned for long-term or short-term use. Many storage units offer climate control, as well as 24/7 access and security. It’s a cost-effective space to store forklifts or pickups when not in use. However, space may be limited so they may be unable to accommodate larger equipment or machines.

- Mesh Cages

Welded mesh cages are another inexpensive way to secure your equipment and machinery. When machines are in operation, wire mesh cages can protect employees working in the vicinity from moving parts or components that may have been dislodged. As a storage solution, the equipment can be kept under lock and key, preventing unauthorized access. These typically come in a modular design so they can be reused and repurposed. It can be assembled indoors or outdoors and can be fitted with a protective covering over or on the sides to keep it safe from sun or rain.

- Off-Site Warehouses

Storing equipment off-site means there is no need to build an additional structure in the area or use valuable working space for idle equipment. Instead, that same area can be used for operations that can yield returns. Warehouses also have ample square footage that will enable you to store several large pieces of machinery in their outdoor or indoor facilities. Many also offer transportation services. These facilities are often located in an accessible area for secure receiving and transport and are equipped with state-of-the-art security, so your equipment is kept safe.

Your company’s equipment and machinery are valuable assets that need to be protected—whether for future use or for reselling. Don’t jeopardize your investment and leaving it for the Rental storage units offer a viable solution to your problem. You can choose between an indoor and an outdoor storage facility.

Ready Machinery Movers is a leading provider of various services including the staging and storing of heavy machinery and equipment. In addition to heavy equipment transportation services, we offer the use of our 16,000 square foot facility on four acres of land in Ontario—with both indoor and outdoor storage areas for your equipment. Our location is easily accessible from the highway and provides ample space for receiving, staging and storing.

To request a quote, fill in our online form or call us toll-free at 1-800-211-2500. With us, your equipment is in good hands till the next time you need it.