Regular maintenance and cleanliness are essential in any workplace. In the manufacturing industry, they are even more so. These can mean the difference between keeping the machines in optimal condition for their performance of daily tasks and needing repairs or replacements. It can also enhance the manufacturing efficiency of your plant.

Here are a few tips for preserving the cleanliness of your machines, equipment, and facility.

The Importance of Cleaning Manufacturing Equipment

Proper, thorough, and regular cleaning and maintenance of machines should be a part of every manufacturing facility’s scheduled routine. While it can be a laborious process, investing in equipment maintenance will yield its return.

Keeping your equipment clean and properly maintained allows you to:

- Extend the useful life of equipment and machinery. Machines are expensive and are usually not easy to acquire. The simple act of keeping them clean extends their lifespan and preserves their efficiency.

- Avoid downtime. Unexpected downtime due to breakage can lead to the costly interruption of the manufacturing process. Downtime consultants shared that factories could lose up to 5% of productivity brought about by machine problems.

- Save money on repairs and/or replacements. The time, labour, and acquisition of new parts can be costly. Cleaning helps you avoid the need to spend on unexpected repairs.

- Meet deadlines. Regular cleaning keeps the equipment running without any interruption so that projects will be completed within the set time.

- Save on energy costs. Cleaning and maintenance reduce energy consumption as machines work efficiently.

- Keep rust at bay. Rust is the worst enemy of machines, but it can be easily avoided by regularly wiping dust and moisture off. Avoid major issues. Small issues are resolved before they grow bigger and become more costly to fix.

- Protect your workers. Injuries and fatalities caused by faulty equipment are reduced.

- Maximize your warranty coverage. This can be done by keeping a detailed service record — something obtained only by regularly maintaining the machines.

- Raise resale value. Cleaning and keeping proper service records allows you to get more out of reselling your machine.

Manufacturing Equipment Cleaning Tips

Manufacturers need to keep their equipment in tip-top shape as even a minute of downtime could mean losing thousands of dollars. Similar to people, machines, too, need to be cared for.

Here are some tips to anchor your production and maintenance routine on:

Keep Machines With By-Products Away From Other Equipment

It is tempting to put all machines together in one production area. However, some machines produce harmful by-products that can affect other machines. For instance, in a plastic recycling facility, the materials are broken down into smaller pieces which can find their way into other equipment through holes and crevices and eventually cause them to malfunction.

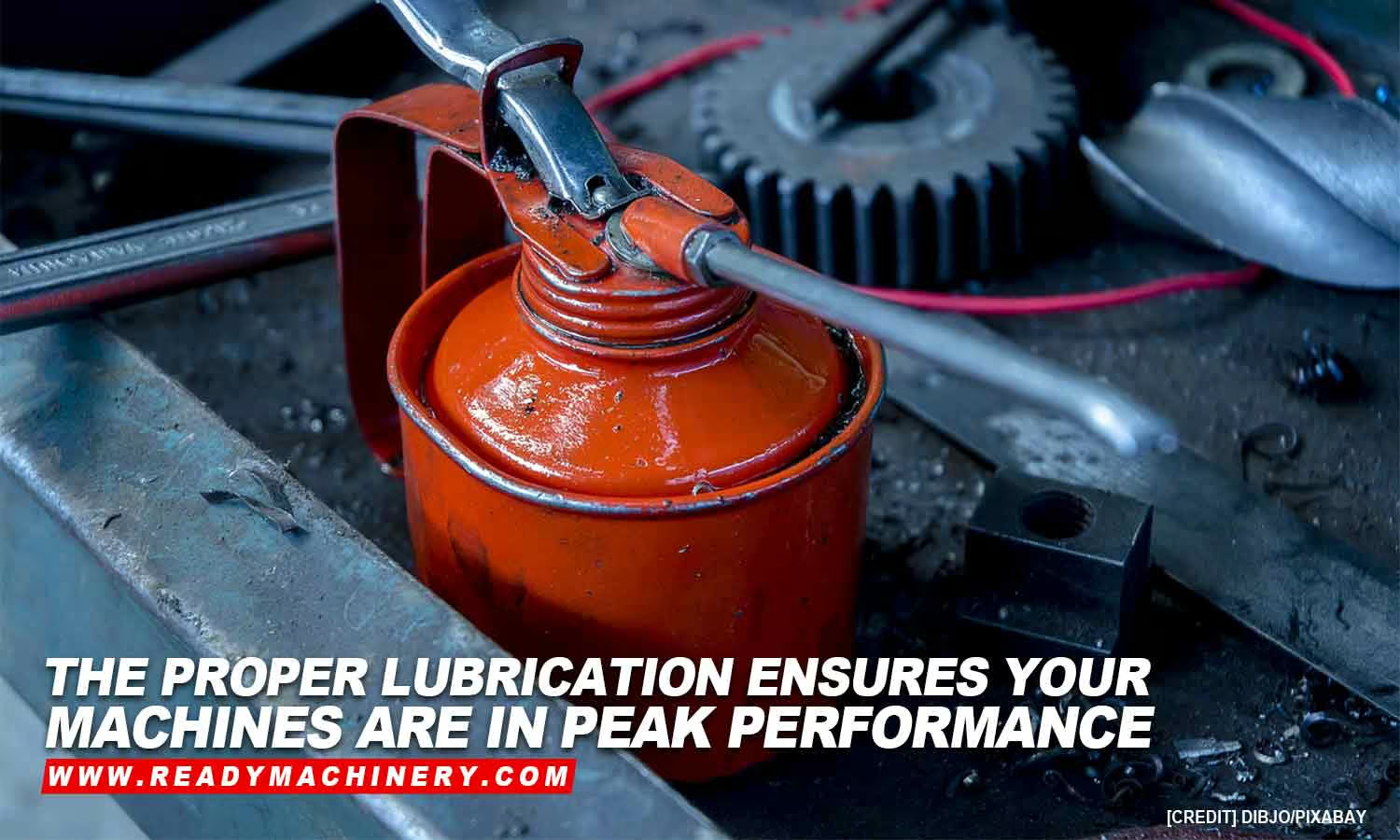

Regularly Lubricate Equipment

Like joints in the body, machines have parts that need to be regularly lubricated to function well. Make it a habit to survey the equipment for signs of excess oil or grease around the pistons. If all of these are in an appropriate amount, you can schedule the lubrication efforts according to the demands of the equipment.

Reminder: Not all lubricants can be used for your machine. Choose only the correct ones as indicated by the machine care instructions. Different components would require different oils and grease so they can function properly. Avoid scrimping by getting lured by a one-product-fits-all mentality since it can only cause you to spend more on future repairs. Studies show that lubrication failure is among the top causes of machine damage.

Invest in Pressure Washers and Water Cannons

Water and soap may not effectively clean machines. Some chemicals claiming to effectively remove grease, excess oil, and dirt may also fall short. Get your equipment a thorough cleansing with the help of a pressure washer.

Pressure washers and water cannons get machines cleaner than manual washing. The powerful hoses release pressurized water that is about 100 to 200 times stronger than normal hoses. For this reason, even the nastiest dirt and grease on machines will be removed.

Always Follow Care Instructions

Each machine comes with specific care and cleaning instructions and these are available for a reason — to maximize the life and service of the equipment. This includes:

- Applying only specific products to the machines

- Using the proper methods to disassemble them for cleaning

- Allocating specific people to troubleshoot them in case of problems.

Manufacturers do not set these instructions for the sole purpose of after-sales services but more importantly because these can promote the best performance of your equipment.

Keep a Cleaning Schedule

A cleaning schedule will save you a lot of money in the long run even if it is just a simple routine. This is not as thorough as it only entails wiping off dust with the use of a damp cloth and removing objects that could get caught in any of the machine’s parts.

Keep Cleaning Records

An accurate cleaning record will come in handy so make it a part of your maintenance and care of machines. There is nothing like arming yourself with the knowledge of every piece of the machinery especially when it is time to address any problem. It is also easier to know your progress so that you can always get back to where you left.

Designate a Regular Cleaner

You could have a regular cleaner in your manufacturing plant but it is always better to have a specific person in charge of cleaning a specific machine. This person will take care of the records-taking, daily checking and cleaning, and of course, overall safekeeping of the equipment.

This task is best assigned to employees who are knowledgeable about that particular machine. If necessary, provide the appropriate training.

Avoid Non-Work Tasks in the Work Stations

Prohibit non-work tasks, like eating, when inside the workstations. Machines are extremely sensitive to moisture that food or drinks have. If these come in constant contact with equipment, it could result in rusting.

Your warehouse cleaning plan is a crucial aspect of your operations. Do not underestimate the value of keeping a clean and organized workspace in cutting downtimes and saving company resources.

Your machines are a central part of your daily processes. If you need to move or store them, turn to a trusted machinery moving company. At Ready Machinery Movers, we place as much value as you would in protecting your machines while transporting or storing them. We are happy to serve you and protect your investment.